Supervisor: Univ.-Prof. Dr Elmar Rückert, Dr. Petra Spörk-Erdely (Chair of Physical Metallurgy and Metallic Materials)

Start date: ASAP from December 2021

Theoretical difficulty: mid

Practical difficulty: low

Abstract

In the context of this thesis, we propose to apply modern machine learning approaches such as variational autoencoder to visualize and reduce the complexity of X-ray diffraction (XRD) data collected on advanced γ-TiAl based alloys. By classifying XRD data collected during in situ experiments into known phases, we aim at disclosing phase transformation temperatures and selected properties of the individual phases, which are of interest with regard to the current alloy development. Furthermore, the capabilities of the applied machine learning approaches going beyond basic XRD data analysis will be explored.

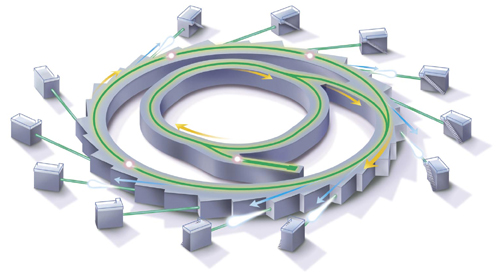

Sketch of a synchron from synchrotron.org.au, illustrating the process of accelerating electrons at almost the speed of light.

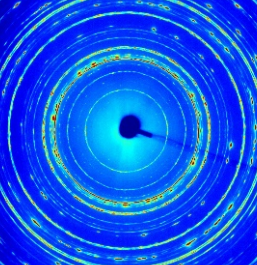

Illustration of a collected data sample which is a 2D X-ray diffraction of a nominal Ti-44Al-7Mo (in at.%) alloy collected.

Topic and Motivation

Intermetallic γ-TiAl based alloys are a promising class of structural materials for lightweight high-temperature applications. Following intensive research activities, they have recently entered service in the automotive and aircraft engine industries, e.g. as low-pressure turbine blades in environmentally-friendly combustion engine options [1].

During the past decades, the development of these complex multi-phase alloys has been strongly driven by the application of diffraction and scattering techniques [2]. These characterization techniques offer access to the atomic structure of materials and provide insights into a variety of microstructural parameters. High-energy X-rays, such as available at modern synchrotron radiation sources (i.e. large-scale research facilities for X-ray experiments), and recent advances in hardware technology nowadays allow to conduct so-called in situ experiments that reveal at a high temporal resolution the relationship between selected external conditions (e.g. thermal or mechanical load) and structural changes in the material. Various specimen environments can be adjusted to emulate technologically relevant or real-life conditions, addressing a multitude of research topics ranging from fundamental questions in the primary alloy design over process-related to application-related issues. Modern setups at synchrotron sources even allow the investigation of elaborate manufacturing, joining and repair processes in an in situ manner, producing insights that have been inaccessible by means of conventional methods so far.

Advanced materials characterization techniques such as described above are often characterized by an ever-growing data acquisition speed and storage capabilities. While enabling novel insights, they, thus, also pose a serious challenge to modern materials science. In situ synchrotron X-ray diffraction (XRD) experiments usually bring about large sets of two-dimensional diffraction data such as those shown in Figure 1. New procedures are needed to quickly assess and analyze this type of datasets.

Tentative Work Plan

To achieve our aim, the following concrete tasks will be focused on:

- Literature research on state-of-the-art materials characterization methods.

- Implementation of deep convolutional neural networks (CNN) and Variational Autoencoder in Python/Tensorflow.

- Application and evaluation of variational autoencoder on the CNN features.

- Analysis and Evaluation of the provided synchrotron data.