Supervisors: Univ.-Prof. Dr Elmar Rückert,

Assoc. Prof. Dr. Susanne Michelic & Assoc. Prof. Dr. Christian Bernhard (Chair of Ferrous Metallurgy),

Markus Brummayer (voestalpine Stahl GmbH)

Start date: ASAP from December 2021

Theoretical difficulty: mid

Practical difficulty: mid

Abstract

In this thesis, the student has the unique opportunity to investigate meniscus level fluctuations in the mold using deep learning approaches at the voestalpine Stahl GmbH in Linz.

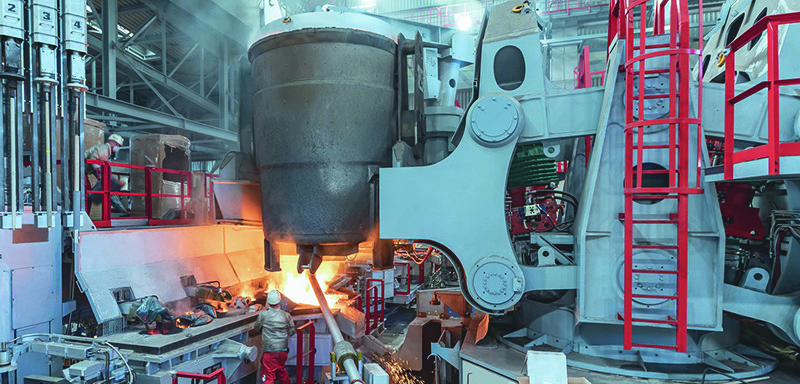

The mold, illustrated in the image above, is equipped with electromagnetic mold level sensors and with temperature image cameras that measure the surface temperature of the casting powder.

The goal of this thesis is to understand and model the underlying dynamic processes of the meniscus level fluctuations in the mold.

In the thesis black box models as well as gray box models that combine analytic dynamic models with learned models will be investigated.

Tentative Work Plan

To achieve our aim, the following concrete tasks will be focused on:

- Literature research on meniscus level fluctuations in the mold.

- Data analysis, filtering, preprocessing, visualization of meniscus level fluctuations data.

- Implementation of deep convolutional neural networks (CNN) as low-dimensional feature extractors. Visualization and analysis of the dynamic processes.

- (Optional) Implementation of neural time-series models like LSTMs trained with the computed CNN features.

- Analysis and evaluation of the provided data.